2021-02-21 Pageview:678

Water-based coating is an environment-friendly product which represents one of the development trends of the coating industry. It mainly includes leather coating, wood coating, floor coating and decoration paint. It is also gradually promoted in metal protection, plastics and automotives. Water-based varnish is colorless, odorless and free of volatile organic compound. With good gloss, folding resistance, abrasion resistance and chemical resistance, it is widely applied to printing inks and packaging including food, drugs, playing cards, cigarette, children’s toys and other special commodities.

It can obtain water resistance, abrasion resistance, adhesion resistance, scratch resistance and better hand feeling by the method of adding wax emulsion in water-based coatings and water-based varnish.

In recent years, wax emulsion with high gloss, high permeability and high abrasion resistance is the higher requirement for water-based coatings and water-based varnish.

New Products

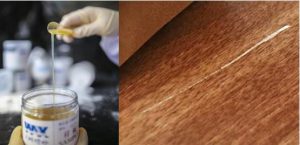

The new wax emulsion OE-6107 developed by Nanjing Tianshi not only meets the core requirements of water-based coatings and water-based varnish, but also with the properties of 100% industrial ethanol resistance, hard water resistance, low temperature resistance, acid and alkali resistance without layering after infinite thinning, and without deterioration and skinning after storing 1 year, thus greatly improving the wear resistance and scratch resistance of water-based wood coatings, water-based plastics and metal coatings.

LW-102A, another waterproof wax emulsion developed by Nanjing Tianshi, is used to improve the water resistance of water-based coatings and varnish. It has very good waterproof, hydrophobic and impermeable effects in the fields like paper, wood, cement and cloth. After adding 5%-20% LW-102A to the coating, water droplets can form perfect lotus leaf-like effects on the surface of the coating, and will not permeate to the back of the coating within 2 hours. Chemical fabric soaked in the system containing 20% LW-102A also has very good hydrophobic effects after drying, and there is no residual water after water flows over the surface of the cloth.

Leave a message

Leave a message

We’ll get back to you soon