2022-01-28 Pageview:1245

Polytetrafluoroethylene (PTFE) is a white waxy thermoplastic with excellent comprehensive properties. Under normal conditions, PTFE has poor radiation resistance and is the least radiation resistant material among all polymer materials, and a dose of several thousand gray (kGy) can completely lose its mechanical properties. Lubricating materials can be manufactured by utilizing the characteristics of PTFE that is easy to be cracked by radiation. Under certain high temperature environment, PTFE can also undergo radiation crosslinking reaction. In this work, the radiation cracking of PTFE and its applications are introduced, and the latest research results on the property changes of cross-linked PTFE and its potential applications are presented.

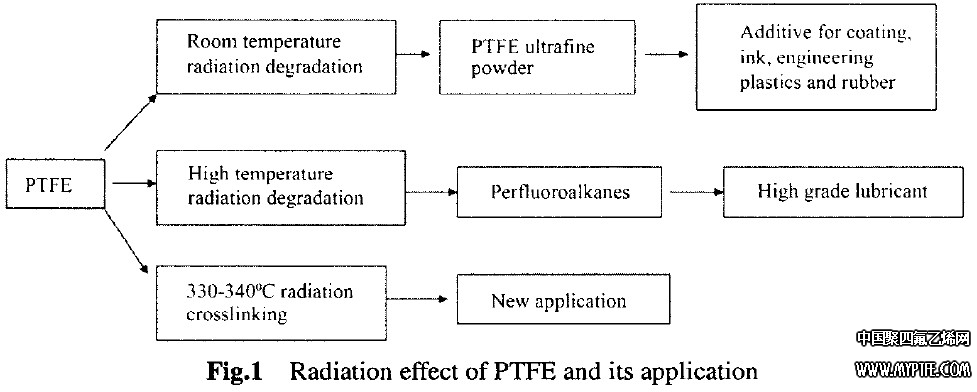

Since the invention of PTFE by Du Pont, PTFE has attracted widespread attention due to its excellent mechanical properties, chemical properties and electrical properties, and has been used in many fields. Compared with these excellent properties, PTFE has poor radiation resistance, so PTFE is widely used in various fields as a typical radiation degradation material. Figure 1 briefly describes the irradiated products of PTFE under different irradiation conditions and its application fields.

It can be seen from the figure that at room temperature or in the presence of air, the carbon backbone of the PTFE molecule can be broken by irradiation with rays or accelerator electron beams, resulting in the cracking of PTFE. PTFE has the characteristics of low friction coefficient and easy radiation cracking. By controlling the radiation dose, combined with grinding or jet pulverization, PTFE ultrafine powder can be prepared. PTFE ultrafine powder is widely used as modifier of engineering plastics, additives for coatings and inks, and additives for lubricating greases. Although PTFE ultrafine powder (even PTFE nano powder) can also be added to lubricating oil as an antiwear agent, but because the density of PTFE is higher than that of oil, the dispersion stability is poor. The long-term dispersion stability of FITE in lubricating oil can be effectively improved by grafting special chemical groups on the surface of FITE. The recycled waste PTFE is made into ultra-fine powder by radiation cracking method, which can be used for engineering plastics or solid lubricating materials. At present, the annual consumption of PTFE ultrafine powder in the world is more than 5000 t. For example, Shamrock Company has three accelerators for the production of PTFE ultrafine powder, and Du Pont of the United States also has a 3 MV accelerator in Shenzhen, my country for the production of PTFE ultrafine powder.

Leave a message

Leave a message

We’ll get back to you soon